| Sign In | Join Free | My himfr.com |

|

- Home

-

Products

- Galvanised Steel Strip(58)

- Galvanized Square Tube(21)

- Hot Dip Galvanized Steel(31)

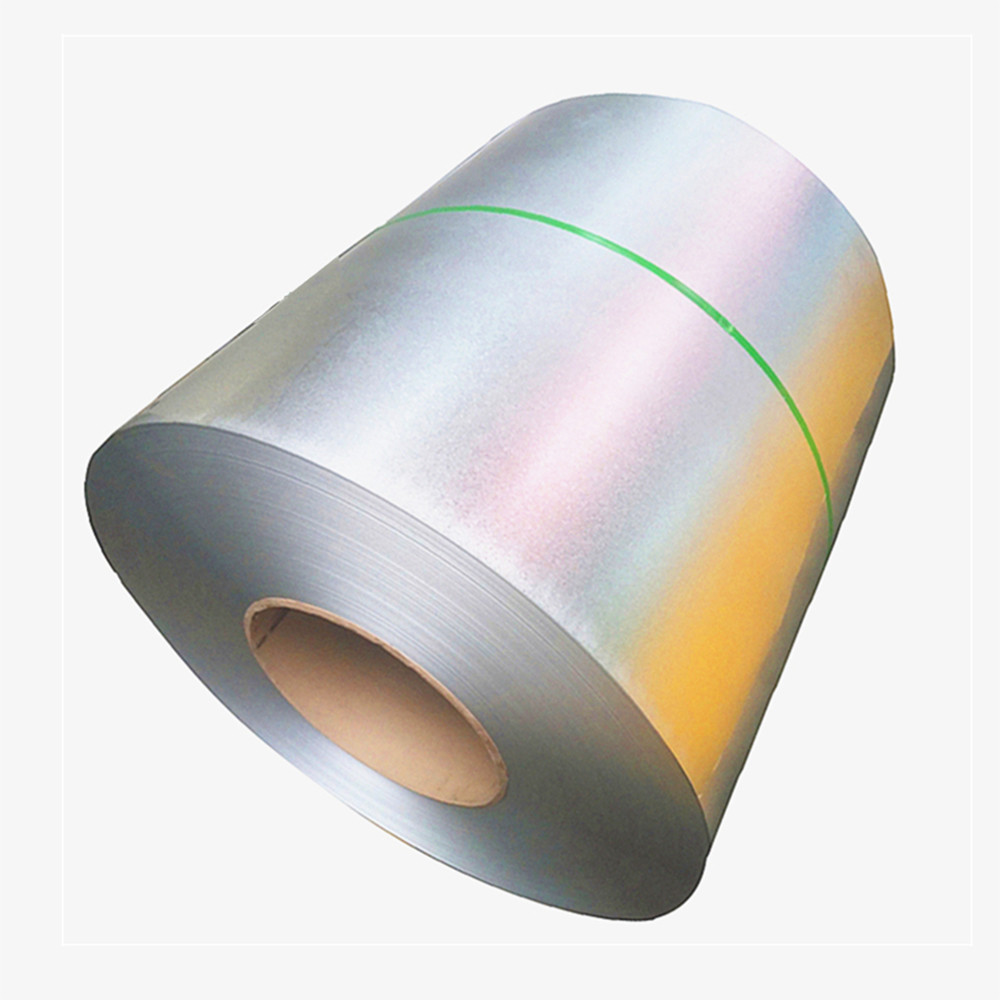

- Galvanized Steel Coil(39)

- Galvanized Round Pipe(21)

- Welded Square Tube(15)

- Welded Round Tube(15)

- Bright Annealed Tube(10)

- Heat Treated Pipe(11)

- Cold Rolled Steel Coil(18)

- Carbon Steel Coil(9)

- Special Steel Pipe(7)

- Embossed Steel Pipe(7)

- Alloy Steel Coil(23)

- About Us

- Quality Control

- Contact Us

- Get Quotations